Our History

The development history of Guangzhou Pinxiu Auto Parts Co., Ltd. can be traced back to 1995, and its development process can be summarized into the following important stages:

Initial establishment and brand establishment

1995

The company's predecessor, Tsannkuen Auto Parts Store, was established and registered the CCL brand, becoming the first batch of auto parts traders with independent brands in China. The focus of this period was on establishing brand image and initial market layout.

Brand agency and business expansion

1997

Tsannkuen Auto Parts Store was renamed Guangzhou Pinxiu Auto Parts Co., Ltd., and successfully represented Japan's NKN ball joints and half-axle series products. At the same time, the company launched a national agency mechanism for the CCL brand, further broadening its business scope.

1999

The agency network in provincial capital cities across the country has been fully rolled out, laying a solid foundation for the company's market expansion across the country.

Quality system certification and branch establishment

2000

The company passed the ISO9001:2000 version of the international quality system certification, indicating that the company has reached international standards in product quality management.

2002

Beijing branch and foreign trade company were established at the same time, marking the company's expansion into the national and international markets.

Information management and brand upgrade

2003

The head office and branches began to use the ERP system, introduced systematic management, and improved the company's operational efficiency and management level.

2005

In order to deepen the development of the CCL brand, the company established a professional technical department and a brand promotion department, focusing on brand building and market promotion.

2007

The brand packaging was fully upgraded, and anti-counterfeiting codes were set up on the packaging to enhance brand protection and market trust.

Owned brand and market expansion

2011

The company established the EQC brand, implemented a dual independent brand operation strategy, and further enriched the product line.

2012

The headquarters office building and warehousing department were relocated, and the office and warehousing area was expanded by more than 3 times, providing greater space for the company's development.

2015

The total sales output value broke a new high, and the vehicle model coverage rate reached more than 90%. The company has established a benchmark position in the industry.

Global layout and technological innovation

2018

EQC's independent brand was fully upgraded to a graphic sign, now EPX, with a more distinct brand image.

2019

A large-scale warehousing and logistics center of 3,000 square meters was established in Zhejiang, which improved logistics efficiency and customer satisfaction.

2020

Fuzhou Branch and Kunming Branch were established to further expand the domestic market.

2021

Accelerate the development of new products, implement comprehensive promotion of new media channels, strengthen brand image output, and enhance market competitiveness.

2022

Introduce PDA system and QR code warehousing system, upgrade and transform the system, and improve the level of information management.

2023

Shenyang Pinxiu was established, and the half-axle warehouse was relocated and expanded by 1,000 square meters, providing strong support for the company's business expansion in the Northeast region.

In summary, Guangzhou Pinxiu Auto Parts Co., Ltd. has gone through a process from start-up to development and growth since its establishment. The company has always adhered to the market-oriented, quality-oriented, continuous innovation and expansion, and gradually grown into one of the leading domestic auto parts suppliers.

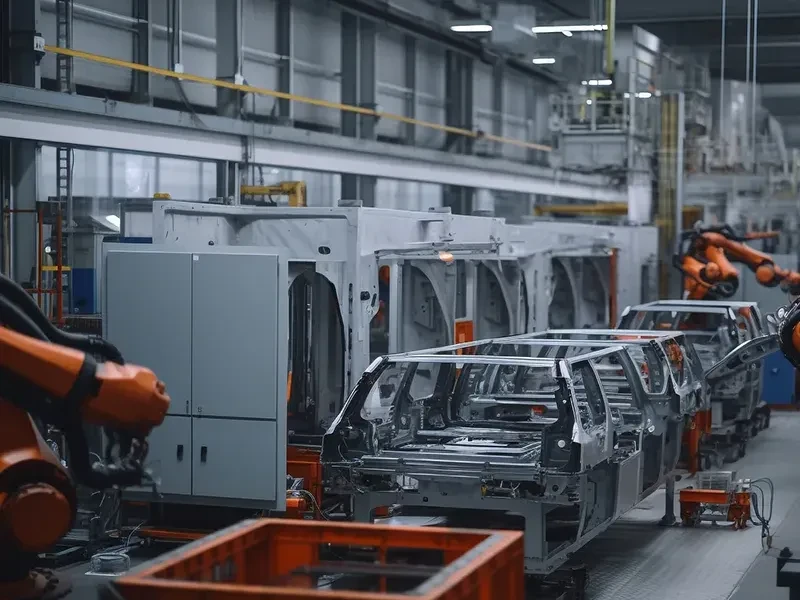

Our Factory

The predecessor was engaged in the production process of precision forging blanks for the main and auxiliary shafts of motorcycles and precision cold extrusion parts, and has accumulated more than ten years of forging production experience.

In 2000, it began to enter the automotive parts manufacturing industry and successfully developed the cold forging blanks of the inner and outer ball cages of the automotive constant velocity joints (C.V.AXLE).

In 2001, the company formed a one-stop production of blanks and finished products, which enabled the company to achieve unprecedented development.

In October 2002, the company passed the ISO9001-2000 product quality system certification.

In recent years, the company has continued to grow and become one of the key manufacturing enterprises.

Enterprise scale and strength

Factory scale

The company covers an area of ?More than 70 acres and has about 200 employees, including more than 20 engineers.

Production capacity

The company has a complete processing system such as forging, turning, heat treatment, and finishing, and can produce high-quality automotive parts.

Technological innovation and products

Focusing on the production of cold forging blanks of ball cage type constant velocity joints and inner and outer ball cages, it is a professional manufacturer in this field.

The company has a number of patented technologies and registered trademarks, such as a constant velocity transmission shaft with a retractable intermediate shaft, a test fixture for measuring the inner groove of the ball cage bell shell, etc. The company has also successively developed innovative products such as a high-performance constant velocity transmission shaft with an outer ball cage with an oil groove and a large swing angle intermediate shaft with large retractability.

Our Product

An automotive parts company integrating R&D, production and sales, its business series of products mainly include the following aspects:

I.Core automotive parts

1. Constant velocity joint/also known as: ball cage: As one of the company's flagship products, the constant velocity joint plays a key role in the automotive transmission system, ensuring the smooth and efficient power transmission.

2. Drive shaft assembly, half-shaft assembly: including various types of drive shafts, these components are an indispensable and important part of the vehicle's driving process, responsible for transmitting power from the engine to the wheels.

II. Shock absorption and suspension system

1. Shock absorber: Provide a variety of shock absorbers, designed to improve the vehicle's driving stability and ride comfort, and reduce the impact of uneven roads on vehicles and passengers.

2. Shock-absorbing spring: Used in conjunction with shock absorbers, it reduces vehicle vibration by absorbing and releasing energy, protecting vehicles and passengers from impact

3. Wheel hub bearings

Other Automotive Parts

Ball cage dust cover: used to protect key components such as ball cages from dust and impurities, extending their service life

Other accessories: The company also operates a variety of other auto parts, such as control arms, suspension ball heads, steering gears, engine mounts, swing arm bushings, etc. to meet the diverse needs of different models and customers.

Product Application

It has a wide range of applications in automotive transmission systems. Its main function is to transmit torque between the output end of the gearbox and the drive wheel, and to keep the drive shaft rotating at a constant speed, ensuring smooth power output even when the axis angle changes.

Our Certificate

Quality Management System Certification ISO9001:2015

Production Equipment

1. Cold forging equipment: used to produce cold forged blanks for inner and outer ball cages. This type of equipment usually has the characteristics of high precision and high pressure, which can ensure the dimensional accuracy and surface quality of the blank.

2. Heat treatment equipment: Heat treatment of cold forged blanks to improve their mechanical properties and processing performance. Common heat treatment equipment includes quenching furnace, tempering furnace, etc.

3. Machining equipment: such as CNC machine tools (CNC machine tools), lathes, milling machines, grinders, etc., used to further finish the blanks to form the final ball cage products. These equipments have the characteristics of high precision and high efficiency, and can meet the processing requirements of complex shapes and sizes.

4. Testing equipment: including three-coordinate measuring machines, hardness testers, metallographic analyzers, etc., used to perform quality inspections on blanks and finished products during the production process to ensure that the products meet relevant standards and customer requirements.

5. Automated production lines: In order to improve production efficiency and product quality, Changzhou Chaoyu Machinery Manufacturing Co., Ltd. may also be equipped with automated production lines to connect cold forging, heat treatment, machining and testing processes to achieve continuous and efficient production.

6. Auxiliary equipment: such as cranes, conveyor belts, cleaning machines, etc., used for auxiliary work such as material handling, transportation and cleaning, to improve the cleanliness and work efficiency of the production site.

Production Market

Domestic market: There are agents in all major cities in China, up to 38 agents

Foreign market: Eastern Europe, Middle East, Southeast Asia, Africa, South America

Our Service

Guangzhou Pinxiu Auto Parts Co., Ltd. has a complete system and process for pre-sales, sales and after-sales services to ensure that customers can enjoy professional, efficient and satisfactory services.

Pre-sales service

1. Product consultation

Provide detailed product information, including product specifications, performance, scope of application, etc., to help customers understand and choose products that suit their needs.

With a professional sales team, we can answer all kinds of questions about products and provide professional suggestions.

2. Technical support

Provide technical support to customers, including product model selection, installation guidance, etc., to ensure that customers can use the products correctly.

3. Customized service

According to the special needs of customers, we provide customized product solutions to meet the personalized needs of customers.

In-sales service

1. Order processing

Quickly respond to customer orders to ensure the accuracy and timeliness of order information.

Provide order tracking services to keep customers informed of the progress of order processing.

2. Logistics distribution

Cooperate with multiple logistics companies to ensure that products can be delivered to customers safely and promptly.

Provide logistics query services to facilitate customers to grasp logistics information at any time.

3. Quality Assurance

All products undergo strict quality inspections to ensure that product quality meets relevant standards and customer requirements.

Provide product quality assurance certificates to make customers worry-free.

After-sales Service

1. Product Replacement

Provide free replacement service. If customers find that the product has quality or material defects within a certain period after purchase (such as within 12 months or within 60,000 kilometers of vehicle travel), the company will replace it for free. However, it should be noted that the product must be accurately installed, debugged, used and maintained, and the installed vehicle has not participated in any commercial activities with intense collisions.

2. Professional Technical Consultation

With professional technicians, we provide technical consultation and solutions to customers to help customers solve problems encountered during use.

3. Complaints and Suggestions

Set up a special after-sales service hotline and complaint suggestion channel. Customers are welcome to put forward valuable opinions and suggestions so that the company can continuously improve and enhance service quality.

4. Maintenance and Maintenance Guidance

Provide maintenance and maintenance guidance for automotive parts to help customers extend product life and improve vehicle performance.

To sum up, Guangzhou Pinxiu Auto Parts Co., Ltd. has a complete system and process for pre-sales, sales and after-sales services, and is committed to providing customers with professional, efficient and satisfactory service experience.